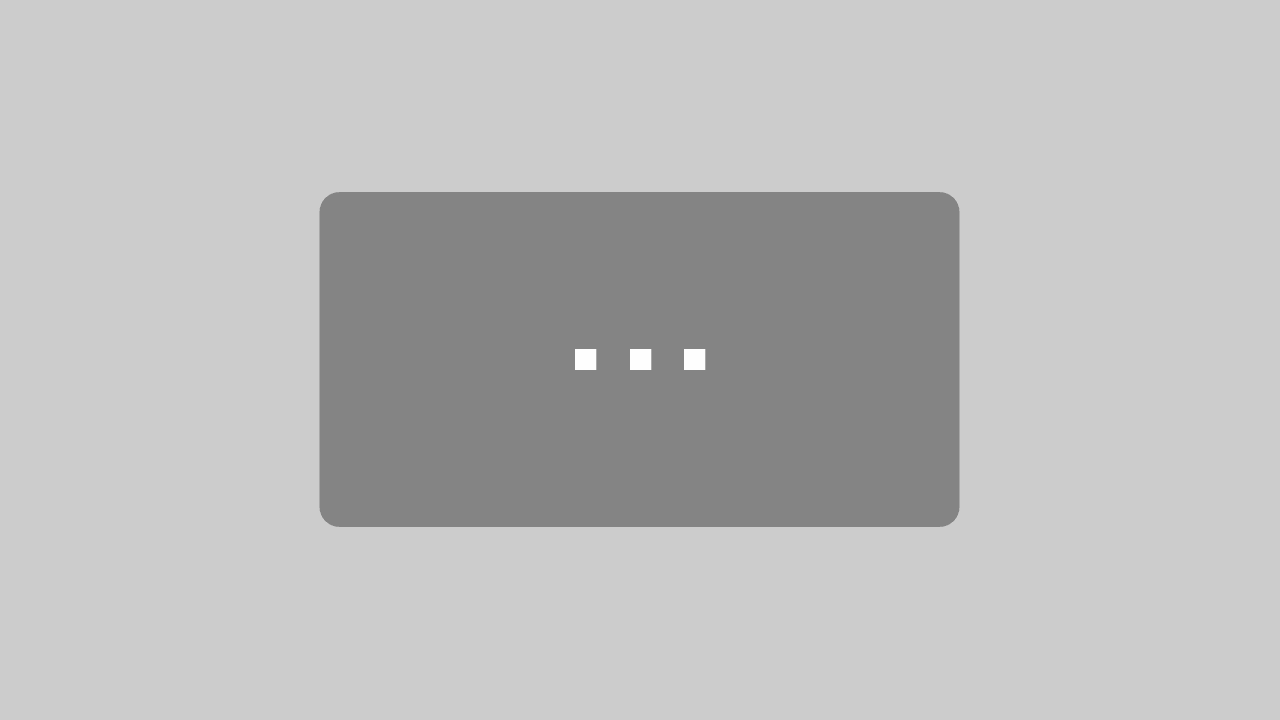

Continuous spray granulation is used when liquids shall be transformed directly into granules of a certain particle size. This animation demonstrates the principle of professional continuous fluid bed spray granulation.

‘Technological Solution for Designing Customised Products from Liquid and Powdered Raw Materials’

Save the date:

- Hyatt Regency, Barcelona, Spain

- November 4, 2024 – 1:15 p.m.

- SULPHUR TECHNICAL SHOWCASES

- Speaker is Dr. Johannes Buchheim, Glatt Ingenieurtechnik

Technological Solution for Designing Customised Products from Liquid and Powdered Raw Materials

Lecture abstract

The processing of powdered and liquid materials into agglomerates and granules has significant advantages. These include the generation of a dust-free, free-flowing product that is easier to transport and dose, leading to better processing at subsequent stages. Technological solutions based on fluidized bed and spouted bed processes are the most suitable choice for the desired particle shaping and optimization of final properties.

Granules are typically produced from solutions, suspensions, or emulsions. These are introduced into the fluidized bed chamber, where the liquid evaporates, and initial granulation nuclei form. During the process, these nuclei are further built-up layer by layer into the final granule by continued spraying of the starting solution, allowing control over the product properties through adjustable process parameters.

Sulphur is an essential element for crop nutrition in agriculture. As a macronutrient, it is involved in the formation of important amino acids and vitamins, and it is an indispensable element in photosynthesis. Fertilizing with elemental, easily spreadable sulphur forms the basis for an adequate supply of cash crops and thus increases crop yields. Additional benefits include sustainable and disease-fighting effects, as well as a positive impact on soil microorganisms, leading to better nitrogen utilization.

But, processing powdered sulphur, can be challenging due to dust formation. Therefore, it is advantageous to convert sulphur into more easily processable agglomerates or granules. Process control can be achieved by utilizing the low melting temperature of sulphur. This enables the production of dust-free, free-flowing products through the aforementioned processes. Spray granulation of a sulphur suspension with appropriate additives results in a rapidly disintegrating granule, ensuring effective and fast conversion to plant-available sulphur. Due to its high-water solubility, the product can also be applied as foliar fertilizer in the form of a sulphur solution using a field sprayer.

The fluidization of solid particles in ascending gas streams can also be used for more complex reactions. For example, H2S can serve as a reactant for the transformation of hydroxides and oxides into sulfidic ceramic materials with applications in energy storage and optical applications.

Thanks to its extensive experience in plant engineering in the field of fluidized bed technology, Glatt offers various possibilities for designing materials with customized properties and throughput rates.

Please note: The lecture will be given in English language.

Sulphur + Sulphuric Acid 2024 Conference & Exhibition

Sulphur + Sulphuric Acid continues to be an essential annual forum for the global sulphur and acid community to learn, connect and do business. Knowledge sharing is at the event’s core: via the respected dual-streamed technical programme, and the connections made with industry experts and solution providers attending.

In 2024, you can expect an expanded market outlooks agenda, including expert insights from CRU’s analysis teams on major supply and demand markets, including sulphur and sulphuric acid, plus additional industry updates from key players from across the supply chain.

Covering technical updates on the production and processing of sulphur and sulphuric acid, will feature industry-leading presentations covering new innovations in process, technology, materials and equipment developments, as well as practical case studies highlighting operational experience and improvement.

Here you’ll find more information on the event program.

Copyright: Glatt

Copyright: Glatt Copyright: Glatt

Copyright: Glatt