Glatt PHOS4green

Proven Process Steps Innovatively Combined

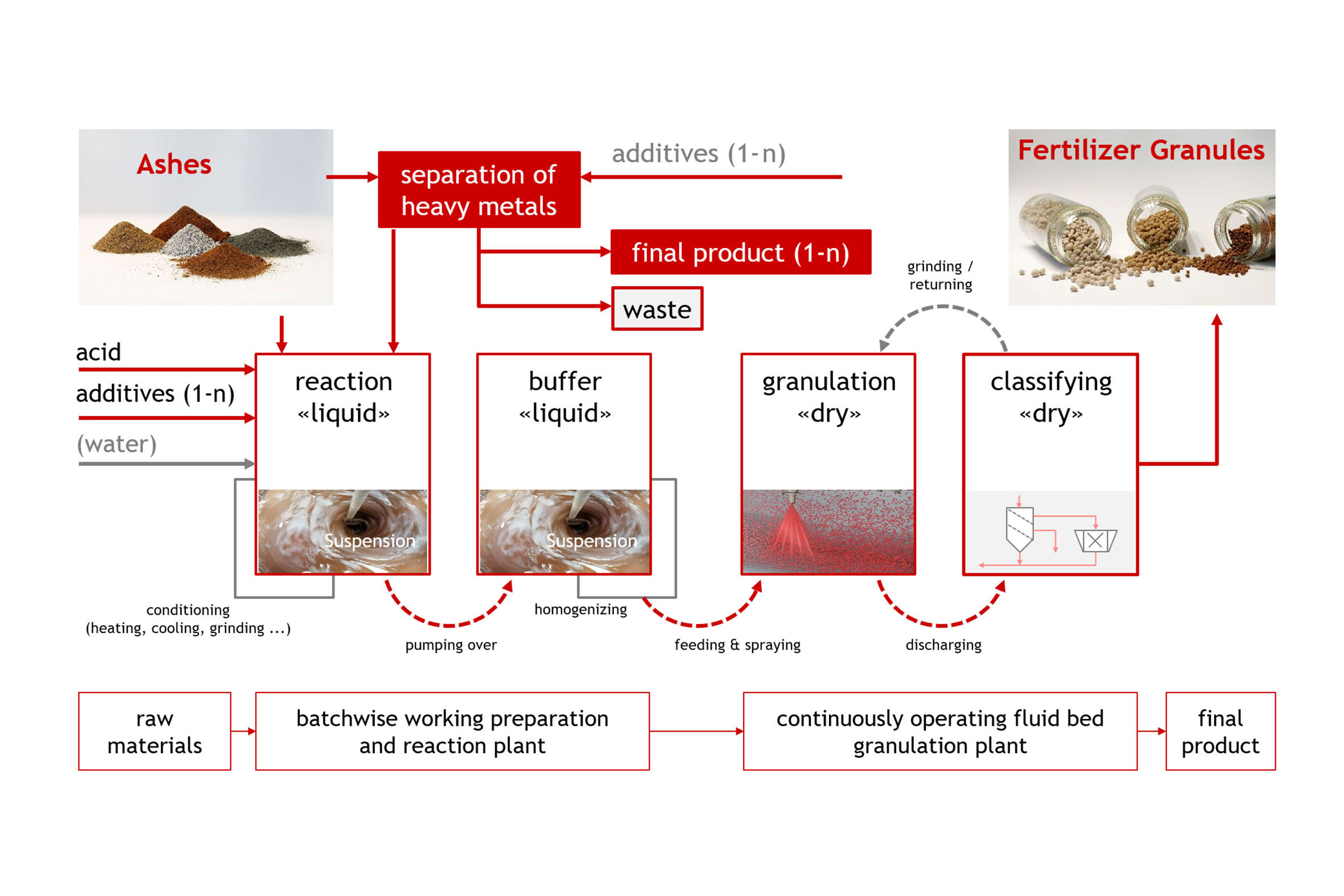

With PHOS4green, Glatt offers an economical and flexible technology for recovering phosphorus from sewage sludge ash. The process combines phosphorus recovery with the manufacturing process for new fertilizer and results in marketable products.

In cooperation with the company SERAPLANT, Glatt has developed an innovative, patent-protected, efficient and marketable process in which a suspension is first produced from the phosphate-containing secondary raw material sewage sludge ash, an acid and possibly other nutrient components. The phosphate in the sewage sludge ash is broken down by the acid.

The suspension produced in this way is then spray granulated in a fluid bed system. In this way, valuable granules are produced that can be used as high-quality phosphate fertilizers or as plant- and soil-specific compound fertilizers, e.g. NP or NPK fertilizers.

The production of solutions or suspensions in combination with acids is a well known practice in the chemical industry. The necessary technology for this is available for every conceivable substance system on an industrial scale. As a first step in suspension generation, Glatt uses this proven technology.

The second process step is spray granulation in the fluid bed, one of Glatt’s core competencies.

PHOS4green combines and optimizes these process steps and thus ensures technical feasibility – immediately applicable also on an industrial scale.

Benefit from our technology competence for a fast and secure implementation phosphorus recycling with well controllable reaction steps!

Contribute with us to the required sewage sludge disposal and to the assurance of a long-term sustainable sewage sludge solution!

Your innovative advantage

That’s what makes the difference between PHOS4green and other phosphorus recovery technologies

How PHOS4green works

How the two-stage, residue-free PHOS4green process turns sewage sludge ash into ready-to-use fertilizer containing phosphorus.

Heavy metal depletion

Compliance with limit values for fertilizers. More disposal safety for sewage sludge ashes.

How granules are made

Transfer of the finished suspension directly into a dry, dust-free granulate with defined properties

Process and production equipment

Best equipped from laboratory tests to your individual fertilizer production plant

Further information on this topic and related topics can also be found in the following publications:

Flyer A4: Glatt Functionalization of Special Fertilizers, PDF, English

Flyer A4: Glatt PHOS4green, PDF, English

Published article: ‘Growing the German phosphate industry’. PDF, English

Published article: ‘Like a phoenix from the ashes’. A recovery technology that releases phosphate from sewage sludge ashes and converts it into ready-to-use fertilizers. PDF, English

Published article: ‘Fomulation For Success – Fluid Bed Systemes as Key for the Production of Speciality Fertilizers’, PDF, English