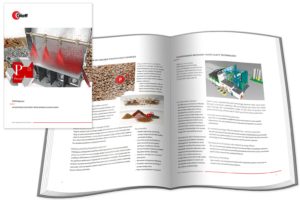

How the two-stage, residue-free PHOS4green process turns sewage sludge ash into ready-to-use fertilizer containing phosphorus.

Efficiency

Moderate process temperatures, low exhaust air temperatures, minimal mechanical stress

Stable Process Control

by separating the process steps into reaction and granulation

Recipe Control

Suspension of ash, acid + optionally other nutrient components

Suspension Batch by Batch

Different reaction kinetics per formulation and raw material composition

Flexible and Capable of Partial Loads

Adaptable drying capacity with constant granulation conditions

No Special Materials

“Dry” process control without corrosion and contact of free acid with components

Stable Raw Material Feeding

Suspension is easier to dose than filter cake, centrifuge cake, wet granulate, extrudate, etc.

Fast Product Changeover

Safe raw material feed via spray system guarantees easy cleaning of the system

Homogeneous Liquid Preparation

All components finely dispersed and homogeneously distributed

In One Step

Convective drying with simultaneous shaping

Effectiveness

Maximum accessibility of the surfaces for the reaction

Heavy Metal Depletion

Pollutant content is significantly below the legal limits

Simple, flexible and stable process control due to separation of the process steps

In this process, the suspension production and thus the reaction of phosphate conversion between phosphate-containing secondary raw material and acid are separated from the granulation process. As a result, the raw material components are homogenized. For the conversion reaction, a suspension is produced from the phosphate-containing ash with the aid of an acid, in which the solid particles are distributed. The aim is to make the ash-based nutrients available to plants. Adapted to the available raw materials, the suspension is customized for the desired fertilizer product.

Depending on the application objective, water and other solid or liquid nutrient components, including additional phosphate sources, are added. The suspension step also makes it possible to better control and manage the tackiness of the system and the exothermic reaction. The high-energy reaction, which sometimes occurs spontaneously and violently when the phosphate-containing ashes and the acid are brought together directly, becomes controllable and manageable. The free acid is already largely converted in the suspension, effectively preventing corrosion of plant components.

Further information on this topic and related topics can also be found in the following publications:

Published article: ‘Like a phoenix from the ashes’. A recovery technology that releases phosphate from sewage sludge ashes and converts it into ready-to-use fertilizers. PDF, English

Published article: ‘Fomulation For Success – Fluid Bed Systemes as Key for the Production of Speciality Fertilizers’, PDF, English

Published article: ‘Growing the German phosphate industry’. PDF, English

March 2021: Glatt Ingenieurtechnik celebrates continued business success with third expansion of its Technology Center

Flyer A4: Glatt PHOS4green, PDF, English