Insoluble phosphates become plant-available through acidity.

Fast, secure implementation. Well controlled

reaction steps.

Consistent end fertilizer quality due to defined formulation of the suspension.

Compensation of different phosphorus contents of sewage sludge ashes.

Profitability and flexibility in volatile markets.

Reduction of disposal and raw material costs.

Heavy metal depletion.

Insoluble phosphates become plant-available due to acidity

Burning sludge to create ashes concentrates the phosphate and removes organic pollutants. These ashes therefore represent a particularly interesting phosphorus source. However, the phosphates present are in an insoluble and thus not plant-available form.

Acids can be used to convert these insoluble phosphates into a form that is available to plants. In a suspension, the poorly soluble phosphate compound is converted in to a plant-available form. The composition of this suspension can be freely defined – even on an industrial scale.

Fast and safe implementation through well-controllable reaction steps

Many alternatively discussed phosphorus recycling processes are not yet technically feasible. They sometimes produce large amounts of waste or require a specific raw material matrix. Often they are based on completely new developments and are determined by very complex and accordingly only very difficult to control process steps such as precipitation reactions or extractions. The proof of technical feasibility often has to be provided first, with a correspondingly uncertain outcome.

With PHOS4green, no expensive, possibly multi-stage extraction and separation processes are used. The process developed by Glatt is based on process steps that have been in use for decades and have been tested and optimized accordingly.

Quality differences of sewage sludge ashes are compensated by formulation

The quality in terms of chemical and mineralogical composition of the sewage sludge ash used as raw material fluctuates. The ash from a single mono-incineration plant has different phosphorus contents over time. Also the ashes of different incineration plants differ significantly with regard to the phosphorus content. Alternative and complex processes for phosphorus or phosphate recycling are sensitive to such quality differences. The dissolution, precipitation and extraction processes in wet chemical processes for phosphorus recycling only run optimally within narrow parameter limits. In technical operation, it is necessary to react promptly to the varying composition of the sewage sludge ash. This is analytically and technically problematic. In such processes, the technical operating conditions will deviate very strongly from the optimum laboratory conditions. As a result, the recycling rate and the separation of heavy metals are significantly below the expectations established during laboratory studies. This makes these processes unattractive.

In the PHOS4green process, the ash is also mixed with the acid. However, the soluble and insoluble fractions are not subsequently separated. Instead, the entire mixture is processed into ready-to-use fertilizer in a subsequent granulation process. This is technologically much simpler, significantly less expensive, and does not generate any waste. Fluctuations in the composition of the ashes are easily compensated for by adjusting the recipe. This makes the process extremely flexible, easy to control and ensures consistently high quality fertilizer.

Constant quality of the fertilizers due to defined formulation of the sewage sludge ash suspension

An essential factor for any recycling process is whether products in demand are created and what prices these achieve on the market. Uncertainty prevails here with other phosphate recycling processes, whether by thermochemical digestion of sewage sludge, by thermochemical or thermoelectric digestion of sewage sludge ash, or by wet chemical processes. All these processes do not produce standard consistent market products to build a business case around. The monetary nutrient value of fertilizers from alternative processes cannot be assessed because no defined nutrient compositions are available. These recyclates are therefore considered low value products on the market. Customization or consistency of the nutrient content is not possible. Undersupply to crops or overfertilization are the consequences. They are not suitable for coverage of plant- and soil-specific nutrient requirements. As a result, they can only be used by farmers as fertilizers to a limited extent.

Lyes, basic salts, etc. can be added to the suspension produced with PHOS4green. This neutralizes any free acid that may still be present or achieves the desired pH value.

Further nutrient components can also be added to the suspension, for example nitrogen (N), phosphate (P), potassium (K), magnesium (Mg), sulfur (S) or vital trace elements. This makes it possible to produce standardized mineral fertilizers with the desired plant- and soil-specific nutrient composition.

High flexibility for raw materials and end products in volatile markets

The markets for raw materials and fertilizers are highly volatile – there are significant fluctuations in price and availability. To ensure sustainable profitability, a process must respond flexibly to such fluctuations and adapt to changing market needs.

Our innovative PHOS4green process can do this. The cost-effectiveness of the proven technology and the resulting range of high-quality standard fertilizers of different compositions allow a flexible response to fluctuating market needs and raw material availability.

The variation of raw materials, such as the use of alternative acids, including sulfuric acid or nitric acid, allows easy adjustment of the suspension formulation depending on the composition and nature of the ash.

Reducing disposal costs and raw material costs in a waste-free sewage sludge exploitation process

Sewage sludge ashes as a waste product from the incineration of sewage sludge in mono-incineration plants generate high disposal costs and these costs will continue to rise in the future. These costs can be greatly reduced by using the sewage sludge ashes as raw materials for the innovative PHOS4green process for the production of fertilizers. Inexpensive residual materials can also be used as additional nutrient components in this process. PHOS4green does not generate any by-products or waste and therefore there are no costs for their disposal.

For sewage sludge ashes that do not meet the quality requirements of the Fertilizer Ordinance – German Düngemittelverordnung (DüMV) and Regulation EG No. 2019/1009 – when processed into fertilizer recyclates, heavy metal depletion is possible as part of the PHOS4green process.

The fertilizers produced contain up to 92 percent less cadmium and uranium than conventionally produced mineral fertilizers. The pollutant content is below the legal limits.

Further information on this topic and related topics can also be found in the following publications:

Published article: ‘Growing the German phosphate industry’. PDF, English

Published article: ‘Improved performance for crop protection products’, PDF, English

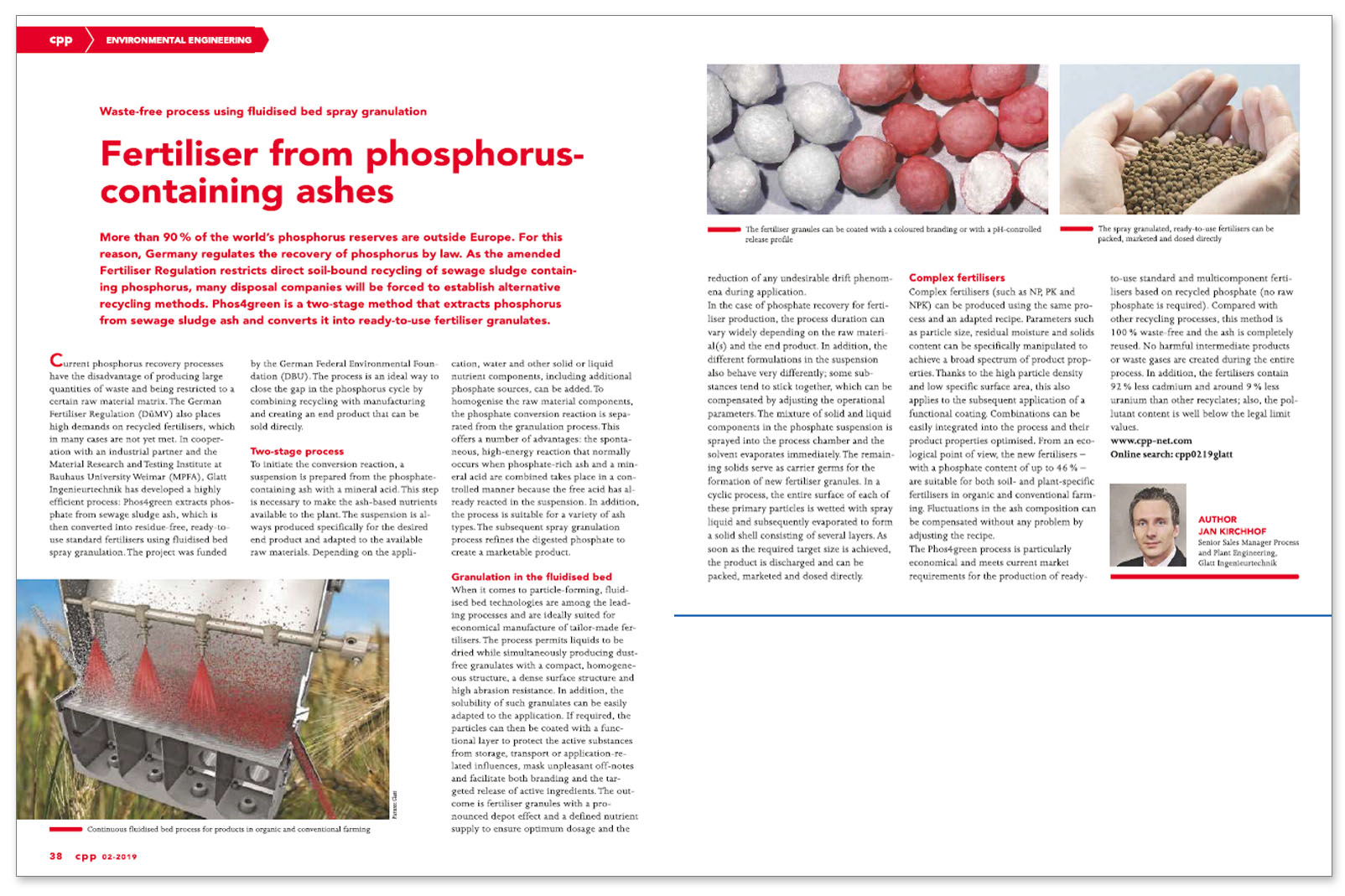

Published article: ‘Fertilizer from phosphorus-containing ashes’ PDF, English

Published article: ‘Like a phoenix from the ashes’. A recovery technology that releases phosphate from sewage sludge ashes and converts it into ready-to-use fertilizers. PDF, English

Published article: ‘Fomulation For Success – Fluid Bed Systemes as Key for the Production of Speciality Fertilizers’, PDF, English