Two-stage process for ready-to-use fertilizers

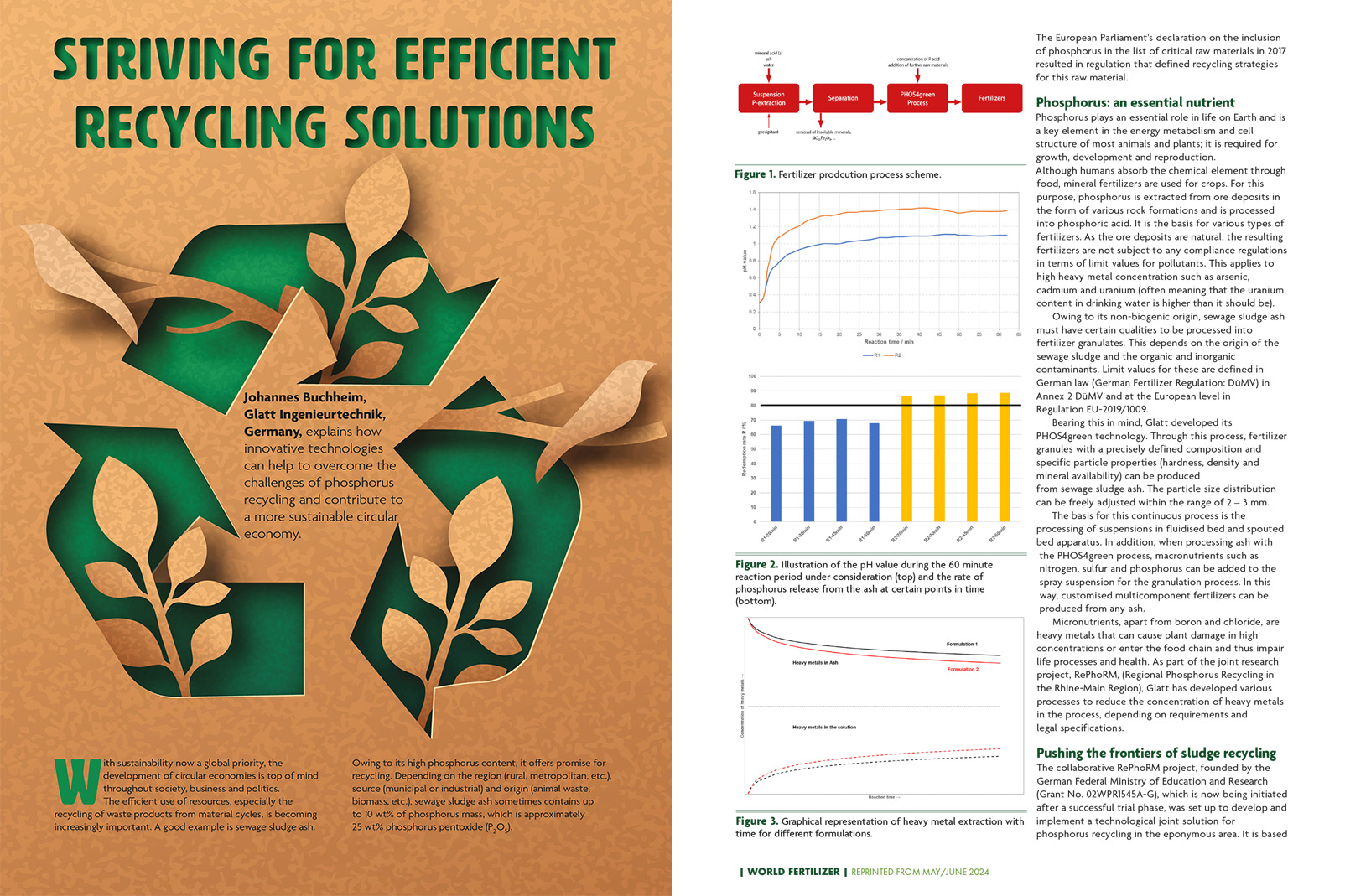

To initiate the conversion reaction, a suspension is prepared from the phosphate-containing ash with a mineral acid. This step is necessary to make the ash-based nutrients available to the plant. The suspension is always produced specifically for the desired end product and adapted to the available raw materials. Depending on the application, water and other solid or liquid nutrient components, including additional phosphate sources, can be added. To homogenize the raw material components, the phosphate conversion reaction is separated from the granulation process. This offers a number of process advantages: the spontaneous, high-energy reaction that normally occurs when phosphate-containing ash and a mineral acid are combined takes place in a controlled manner because the free acid has already reacted in the suspension. In addition, the process is suitable for a variety of ash types. The subsequent spray granulation process refines the digested phosphate to create a marketable product.

Spray granulation in the fluid bed

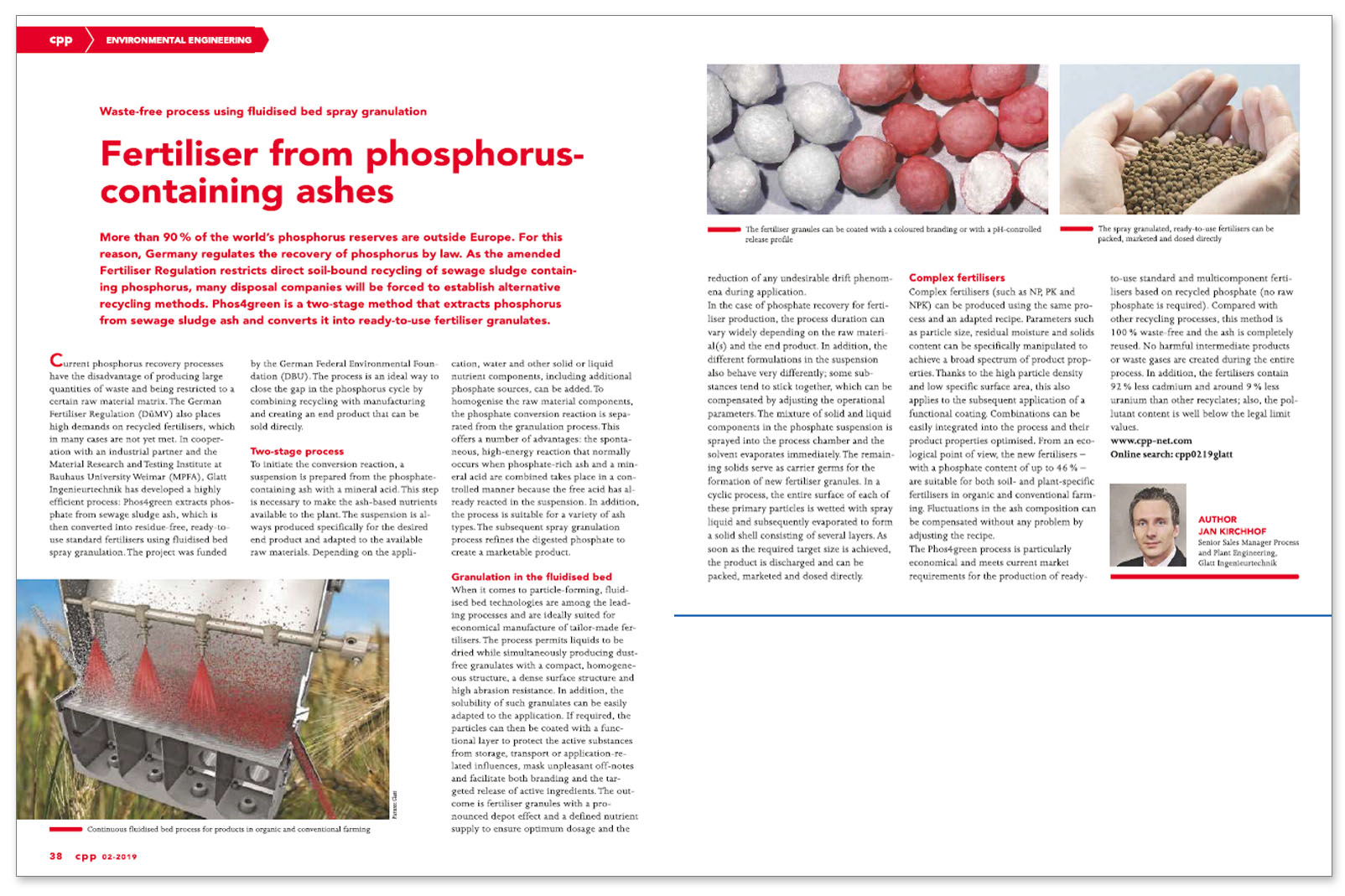

When it comes to particle-forming, fluidized bed technologies are among the leading processes and are ideally suited for the economical production of tailor-made fertilizers (Fig. 1). The process permits the drying of liquids while simultaneously producing dust-free granulates with a compact, homogenous structure, a dense surface structure and high abrasion resistance. In addition, the solubility of such granulates can be easily adapted to the application. If required, the particles can then be coated with a functional protective layer to protect the active substances from storage, transport or application-related influences, mask unpleasant off-notes and facilitate both branding and the targeted release of active ingredients (Fig. 2). The outcome is fertilizer granules with a pronounced depot effect and a defined nutrient supply for optimum dosage and the reduction of any undesirable drift phenomena during application.

In the case of phosphate recovery for fertilizer production, the process duration can vary widely depending on the raw material(s) and the end product. In addition, the different formulations in the suspension behave very differently; some substances tend to stick together, which can be compensated by adjusting the operational parameters. The mixture of solid and liquid components in the phosphate suspension is sprayed into the process chamber and the solvent evaporates immediately. The remaining solids serve as carrier germs for the formation of new fertilizer granules. In a cyclic process, the entire surface of each of these primary particles is wetted with spray liquid and subsequently evaporated to form a solid shell consisting of several layers (Fig. 3). As soon as the required target size is achieved, the product is discharged and can be packed, marketed and dosed directly (Fig. 4).

Complex fertilizers from adapted formulations

Complex fertilizers (such as NP, PK and NPK) can be produced using the same process and an adapted recipe. Parameters such as particle size, residual moisture and solids content can be specifically manipulated to achieve a broad spectrum of product properties. Thanks to the high particle density and low specific surface area, this also applies to the subsequent application of a functional coating. Combinations can also be easily integrated into the process and optimized with regard to product properties. From an ecological point of view, the new fertilizers — with a phosphate content of up to 46 percent — are suitable for both soil- and plant-specific fertilizers for organic and conventional farming. Fluctuations in the ash composition can be easily compensated for by adjusting the recipe.

The PHOS4green process is particularly economical and meets current market requirements for the production of ready-to-use standard and multicomponent fertilizers based on recycled phosphate (no raw phosphate is required). Compared with other recycling processes, this method is 100 percent waste-free and the ashes are completely reused. No harmful intermediate products or waste gases are produced during the entire process. In addition, the new fertilizers contain 92 percent less cadmium and around 9 percent less uranium than other recyclates; also, the pollutant content is well below the legal limit values.

Copyright: Palladian Publications

Copyright: Palladian Publications Copyright: Wiley-VCH Verlag

Copyright: Wiley-VCH Verlag